Installation (with pictures)

Special thanks to Ganesh for this time and effort in taking these pictures (and much more in my hard disk) during his airconditioner installation.

It is quie normal to use duct tape to join the insulation together. The other method is to use suitable glue.

AC Materials (Insulation)

- In this case, the brand is "Superlon".

- 1/4" ID means 1/4 inches internal diameter.

- 1/2" TK means 1/2 inches in thickness.

- What is perhaps missing is the 'Class' standard. It should be preferbably 'Class 1' or 'Class O'

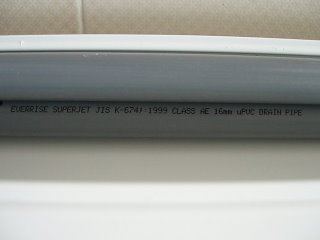

AC Material (PVC Drainage Pipe)

- In this case, the brand is 'Everrise Superjet'

- 16mm means 16mm in external diameter.

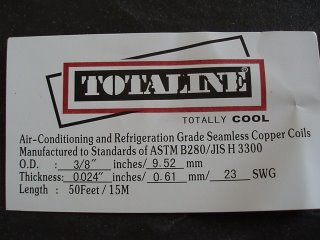

AC Material (Copper Pipe)

- In this case, the brand is 'Totaline'

- OD 9.52mm means Outer Diameter 9.52mm

- Thickness 0.61m / 23 SWG means 0.61mm thick / 23 Standard Wire Gauge

- Length 15m means this copper comes in 15meters per set.

Good work practice

-the worker uses the carton box from the airconditioner as a protection to the owner's flooring. This is especially important if your's is a laminated or parquet flooring. Surely the other choice is to have your airconditoner piping installation completed first before the flooring.

Noticed how the installer uses the trunking to make a protrusion around the stainless steel bracket mounting. When everything is completed, the installer will use a plywood to cover it so it looks like a 'box up'.

This is how a 'Back to Back' installation will look like from the 'other side'. Basically you will not see any trunking as the piping is hacked through from behind.

This is how Sharp Plasmacluster looks like during the dark when the Plasmacluster function is in operation.

Your Responsibility

After you have purchased your air con, you are automatically subjected to these rules.

1) You shall be responsible for the proper installation,safety and stability of your air con.

2) You must ensure the installer is BCA trained. ( except for those who has air con ledge or your outdoor unit is placed inside your flat. )

3) You must ensure the running current of your air con does not exceed the current limit of your flat.

4) You shall ensure all installation works, position of outdoor unit and safety precautions are done properly.

REMEMBER! it is YOUR RESPONISBILITY!

*you can refer to the Guidelines provided by HDB and BCA.

What you should do during the day of installation

Before the Installers arrive

1) You should request the installers to give you a call half an hour before they arrived. If you do not receive the call half an hour before the installation time, you should give the company a reminder call...just in case they 'FORGOT' the appointment after you paid your deposit.

When the Installers arrived

1) You should check that they are installers and not robbers before letting them into your home.

2) Be friendly! and offer them coffee or drinks. A happy installer is a good installer.

3) Request that you would like to take a look at the installation materials. You should have those promised by the salesman only.

If you noticed any materials that are incorrect, sound off to the installers.

If this does not help, give the company a call.

If that also does not help, tell the company that you will not proceed with the installation unless they can prove that the materials are of equalivalent standards.

If all fails, then request to install another day caused you have to go to CASE now!!

( By the way, you should have everything written black and white on the invoice initally, if this is not done...then...you can nothing do about it. Blame yourself!!! )

4) If your air conditioner requires a stainless steel bracket, according to HDB rules, your installer must be a BCA trained worker, so check their certificate. If they do not have with them, you can get their names and go online and check. https://www.bca.gov.sg/citi/trained_inst.asp .

5) If you already had a site survey, remind the installers where the indoor units will be installed and how the piping will be run. And emphasize the important points..like this area will be concealed by a built-in wardrobe so insulation should be thicker (as promised during the site survey if you ever had mentioned ).... or remind them to place protection on your beloved parquet flooring or point out where the concealed water and gas pipes are in the wall.

6) If you had not have a site survey, spend some time to discuss with the installers.

During the Installation

1) If you are not very busy, spend half an hour or so to look at how the installers are doing their work. You can always get your renovation contractor to do the checking and supervision but i always doubt they have the time to do that.

2) Come back about an hour before the end of the installation to take a look at the installation. Look at every part of the installation and sound off any areas that you want to touch up.If you have installed the equipment, test the air conditioner yourself.If you only installed the piping, get them to cover up the exposed copper pipings ends. If everything is ok, say thanks!!!!!

3) If you have requested for 2 times installation, remember to book your next installation date as the company will usually have to arrange for the same team of workers to come back.

After the Installation

1) You should test the air conditioner for at least 2 hrs for any problems like leakage and condensation. If everything goes well, make your way down to the shop to pay the balance. If the whole experience is a good one, praise them.You should NEVER delay the final payment..especially when the installers had done a good job.

2) If there is a problem, get them to rectify before you make your full payment. But when all is ok and you are satisfied with your aircon, do not delay the remaining payment.

Note:There is usually a 'Test Run' procedure stated in the operation / installation manual where the system will check for errors.

Final Steps

1) At the end of everything, you should be given a warranty card each for every outdoor and indoor units. ( Example, a System 3 will have 1 for outdoor and 3 for indoor units ).

If the company do provide installation warranty, make sure you are given one too if they are not using the sales invoice as one.

Note:You should not be reading the installation warranty card for the first time here.You should have requested to see the installation warranty before your purchase.

All you need to know about Copper in air conditioning

COPPER

The most widely used copper type for refridgeration systems is Copper UNS No. C12200 (Phosphorus Deoxidized Copper).

It is actually a type of Wrought Copper Alloy with 99.9% copper and some alloy elements.

Generally if u are using the same copper type as the one i mentioned above, u will be in the majority. Fear Not!

DIAMETER

What is so important abt copper pipe diameter?

CAUSED the manufacturer specified this in their catalouge!! If it is not important then why the manufacturer bothers to specific! Understand?

Generally

1) Liquid Pipe Diameter(from outdoor to indoor) is 6.35mm or 12.7mm for most brands.

2) Gas Pipe Diameter (from indoor to outdoor) is 9.52mm for 9K btu fan coil, 12.7mm for 12k & 15k btu fan coil and 15.88mm for 18k & 24k btu fan coil for most brands.

**Please refer to individual catalogues for more details.

3) Thickness of the copper pipe generally range from Gauge 25(0.51mm) to Gauge 22(0.71mm) with most of the installers using either Gauge 24(0.56mm) or Grade 23(0.61mm)

** U can try asking the salesman to provide a 12.7mm copper pipe for a 9k fan coil and expect the fan coil to blow out 12K of cold air. BUTZ! dun expect the manufacturer to warranty your air con after that. **

THICKNESS

So what is that 'Grade 23' that the salesman just mentioned?

It sounds like the quality of copper, accordding to the salesman this is actually the better grade....or is it true......

The 'Grade' ( in actual fact it is called Gauge rather than Grade. If you want to be more accurate then it is SWG or Standard Wire Gauge ) is actually an industrial term for copper thickness ( in actual fact for most metals )

** Actually i have no idea who started to use Grade......maybe mentioning Grade will sound better but some consumers might mistaken it as a measurement of quality.

Example, Grade 22 is 0.71mm, Grade 23 is 0.61mm and Grade 24 is 0.56mm

This has nothing to do with the chemical content. But generally, a thicker copper is able withstand a higher operating pressure. Surely the manufacturing process also plays a very important part.

But due to copper being the most expensive material in the air con installation, most installers will use Grade 24 if not Grade 23.

Some will even think of ways to 'downgrade' the copper pipe sizes especially with the ever increasing copper prices.